Intelligent Visual Inspection

Quality is critical in modern manufacturing. From surface finishing to final assembly, even the smallest defects can lead to costly rework, warranty claims, or dissatisfied customers. Traditional inspection methods are either manual (slow, inconsistent) or rigid (hard to adapt to new products).

At Nordbo Robotics, we take a smarter approach: combining AI model training with automated optical inspection systems to deliver consistent, reliable, and scalable quality control.

Why Intelligent Visual Inspection?

List and describe the key features of your solution or service.

Consistency

Detect defects with the same accuracy every time

Efficiency

Inspect faster and reduce bottlenecks

Scalability

Apply the same inspection standard across all lines and sites

Traceability

Digital records of inspection results support compliance and improvement

Our Approach

AI Model Training (Phoenix)

Operators train inspection models by simply showing examples of defects on images.

- No coding required – just point out the issues

- Supports scratches, dents, miscoloring, cracks, and more

- Models are deployed to Nordbo Edge devices for real-time inspection

- Continually improved as more data becomes available

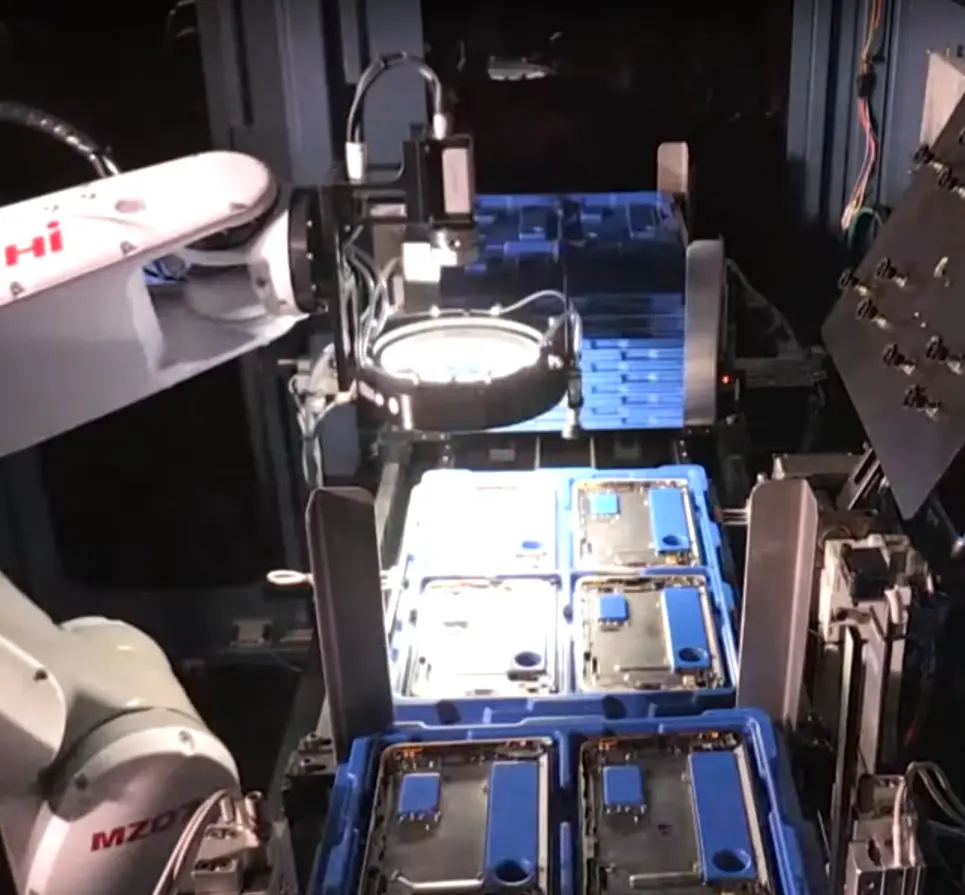

Automated Optical Inspection (Hawk)

Hawk is our ready-to-use AOI platform for surface quality assurance.

- Inline inspection of parts in production

- Detects defects consistently and objectively

- Adaptable to multiple materials and part geometries

- Provides operators and managers with real-time feedback

Business Value

Implementing Intelligent Visual Inspection brings measurable value across production, quality, and customer satisfaction:

Reduce Scrap and Rework

Defects are caught early, before they move further down the line or reach the customer. This reduces material waste, rework hours, and production delays.

Ensure Consistent Quality Across Shifts and Sites

Unlike manual inspection, which depends on operator experience and attention, automated inspection applies the same standard 24/7 — ensuring every part meets the same quality criteria, whether produced today, tomorrow, or at a different facility.

Shorten Production Cycles

Manual inspection is slow and creates bottlenecks. Intelligent inspection automates the process inline, removing delays and keeping throughput high without sacrificing quality.

Improve Customer Satisfaction and Trust

Deliver products with fewer defects, backed by digital inspection records. This builds stronger customer relationships and reduces warranty claims.

Enable Data-Driven Improvement

Every inspection generates structured data. This can be used for process optimization, identifying recurring defect patterns, and supporting continuous improvement programs.