Machines for Automatic Robot Grinding and Deburring

From heavy-duty grinding to precision deburring, Nordbo Robotics delivers standardized machines that are flexible, easy to use, and built for industrial performance.

Why Automate Grinding & Deburring?

Consistency & Quality

Manual grinding and deburring often lead to variation from part to part. Automation ensures a uniform finish, precise edge removal, and repeatable quality across all batches.

Worker Safety

Grinding and deburring create dust, sparks, and vibration — exposing workers to unhealthy and risky conditions. Robots take over the heavy, dirty, and dangerous tasks, allowing your team to focus on higher-value work.

Throughput & Efficiency

Manual work is slow and difficult to scale. With automated grinding and deburring, you can achieve higher output, reduce bottlenecks, and handle more parts per shift without adding more manpower.

Flexibility

Parts come in many shapes and sizes, and production needs change. Our machines are designed to quickly switch between programs, giving you flexibility whether you run high-volume series or smaller, varied batches.

Casted Part Examples

Furniture

Cylindrical

Automotive Exterior

Outdoor

Die Cast

Housings

Nordbo Material Removal Systems

Our Standardized Machines

Compact, versatile solutions designed for small to medium parts with advanced programming and finishing technologies.

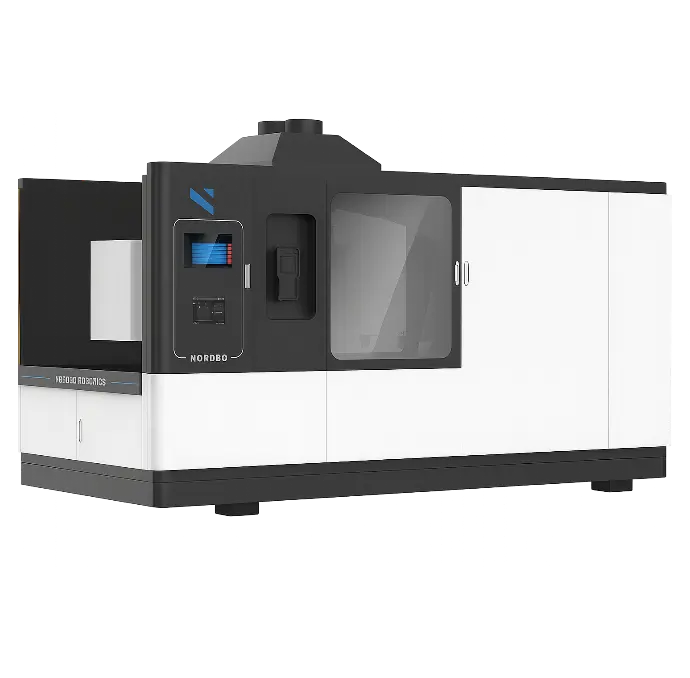

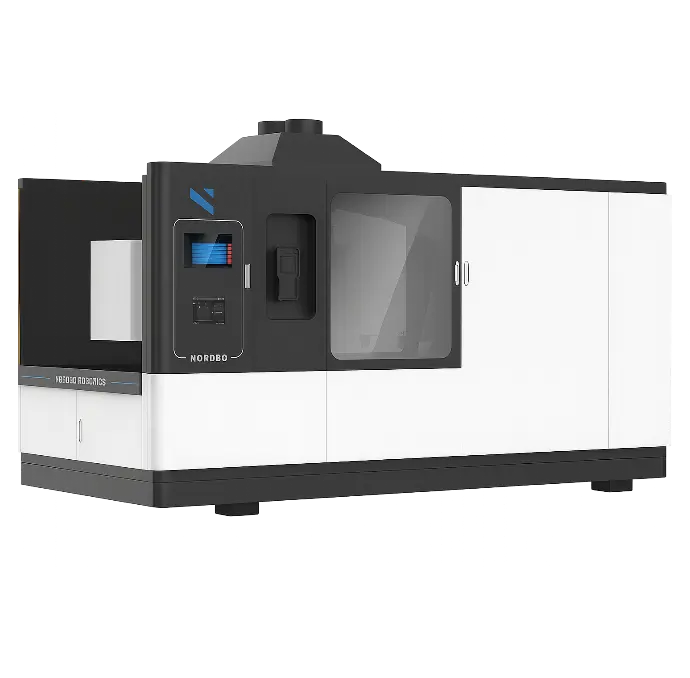

NMRS-600T

Tool in Hand Machine

Efficient, reliable machines for parts up to 600×600×600 mm.

- Can be equipped with multiple grinding or deburring tools. Possibility of tool change.

- Suited for low - mid volume production

- Easy to program with Mimic or traditional teach pendant programming.

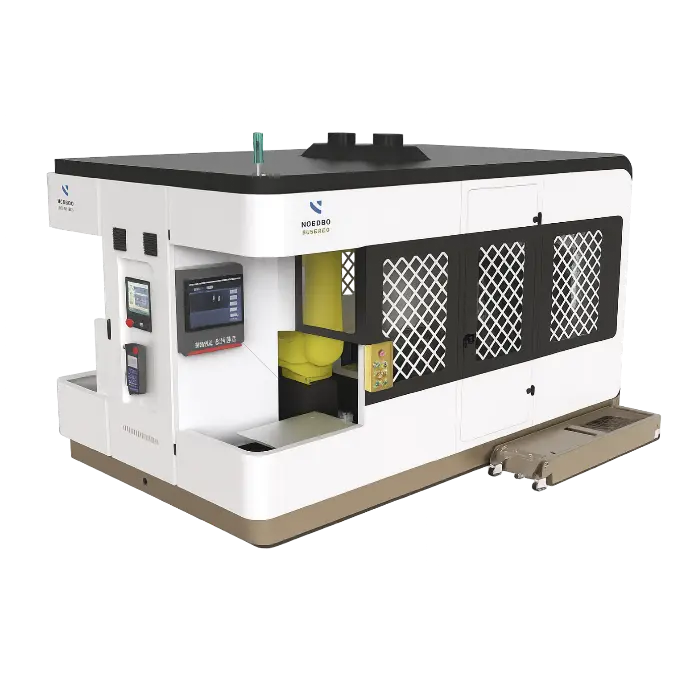

NMRS-500P/700P

Part in Hand Machine

Efficient, reliable machines for parts up to 500×400×200 mm to 500x700x200.

- Enables combination of grinding, deburring, sanding, or polishing in one cell.

- Suited for mid - high volume production

- Perfect for workshops with varied part requirements.

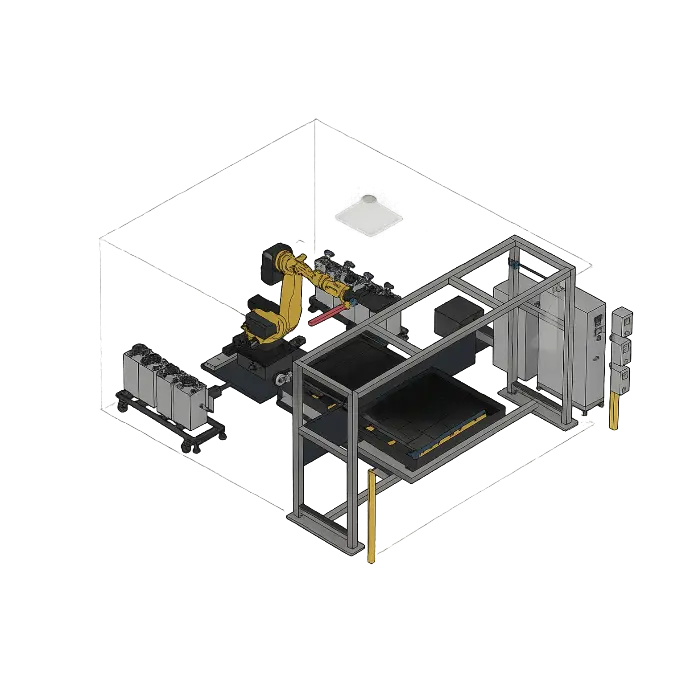

NMRS-1000C

Custom Machine. For parts >600x600x600 mm.

- Tailored for your unique parts and production needs.

- Configurable with special fixturing, tools, and automation options.

- Ideal for industries with demanding quality standards.

Part-in-Hand vs. Tool-in-Hand

Choosing the right setup depends on your parts, processes, and flexibility needs.

Part-in-Hand

- The robot moves the part against one or several fixed tools.

- Best suited for small to medium parts.

- Simplifies fixture design.

- Enables cost-effective use of multiple tools in one setup.

Tool-in-Hand

- The robot holds and moves the tool around a fixed part.

- Works well for larger or heavy parts where moving the part is impractical.

- Can be applied to all part sizes when combined with Mimic, allowing operators to create programs for new parts quickly.

Build with Machine Experts

Expertise Consulting

The Right Solution

- for You

Demonstrate

Construction, Verification & SAT

Commissioning, FAT & Training

Key Features in NMRS Systems

Advanced programming and automation technologies ensure consistent quality, flexibility, and efficiency.

Minimize Programming Time - Even for Complex Parts

Utilize Nordbo fast programming tools & transfer know-how

Program in minutes, not weeks. Skilled operators can transfer their expertise directly to the robot, creating programs in minutes without coding.

Adapt Seamlessly to Part Variations

Compensate for variations and pose changes using advanced scanning

Scanning not only compensates for part variations but also enables pose detection and integrated quality control.

Adapt to High Tolerance and Achieve Consistent Finishing & Longer Tool Life

Force Feedback Optimization & Tolerance Handling

Force feedback automatically tunes programs for consistent finishing, compensates for tolerance variations, and improves tool life.

Ensure Uniform Results on Complex Shapes

Passive & Active Compliance

Simplifies programming (with or without Mimic) and ensures smooth, uniform finishing across complex geometries. Designed to compensate for variations in the part or tooling, ensuring accurate and consistent processing.

Flexible Programming Options

Choose the programming approach that best fits your workflow and part variation.

No Need for Advanced Programming Skills

Utilize operator know-how in minutes. With Mimic, skilled operators can demonstrate the grinding or deburring task directly for the robot. The robot adapt in real time, enabling fast setup for new parts without coding.

Streamline Precision Workflows with CAD/CAM Import

For parts already designed in CAD, tool paths can be generated and imported directly into the system. This is ideal for repeatable, high-precision processes.

Maintain Accuracy Despite Part Variations

Automatically align scanned parts and adjust paths to match real-world tolerances. Ensures accuracy even with part variation.

We Don’t Just Deliver Machines – We Deliver Success

- On-site training for operators.

- Remote and ongoing support.

- Program creation service: Nordbo engineers can build new grinding/deburring programs for your new parts.

Our latest content

Check out some of our stories on grinding, deburring & sanding

Ready to streamline your grinding and deburring?

Let’s discuss how our machines can fit into your production.