Mimic

Teach robots by showing them

Mimic is an easy-to-use platform that allows anyone to record and automate tasks without any programming experience. Operators simply record, transfer, and replicate their own movements, making automation easier than ever before.

With Mimic, you can remove hours of robot programming and let any operator teach the robot directly.

Why Mimic?

Robots are powerful, but programming them has traditionally been slow, expensive, and dependent on experts. Mimic changes that.

By allowing operators to simply show the robot how a task should be done, Mimic removes the coding barrier and makes automation accessible to everyone on the shop floor. The result is faster deployment, lower costs, and a workforce that can control automation directly.

No programming required

Anyone can teach the robot by demonstration

Fast setup

Record, replicate, and deploy in minutes instead of weeks.

Flexible use

Combine with other programming methods when needed

Proven in industry

already used for sanding, polishing, buffing, painting, powder coating, sandblasting, grinding, and deburring

Different Ways to Program with Mimic

Mimic isn’t limited to human demonstrations. You can combine several programming methods in one process:

- Teach by Demonstration – capture operator movements directly

- Path Generation – automatically generate pre-specified robot paths

- Point-to-Point – define waypoints for structured tasks

- Tool Tracking – record paths by moving the tool freely in space

- Part Tracking – let the robot manipulate the part and press it against one or more stationary tools in the workspace (ideal for buffing, grinding, or wheel-based finishing processes with smaller parts)

Tracking Technologies

Mimic is built to work with multiple tracking technologies — and even extend to new ones via its open API. This makes it adaptable to different applications, budgets, and precision requirements.

Default Tracker

IR Tracker

The standard option is based on infrared (IR) tracking, commonly used in VR gaming. A base station emits IR light, and the tracked device — equipped with more than 10 sensors — calculates its pose relative to that signal.

- Advantages: cost-effective, easy to set up, widely available

- Limitations: lower precision, best suited for less demanding applications

High-Precision Tracking OptiTrack

For applications requiring high accuracy, Mimic supports OptiTrack, a camera-based system that uses 2–many cameras to track passive or active markers in the workspace. The system computes precise poses in 3D space, enabling exact replication of complex movements.

- Advantages: very high precision, scalable to larger workspaces

- Limitations: higher cost, more complex installation

Guidance

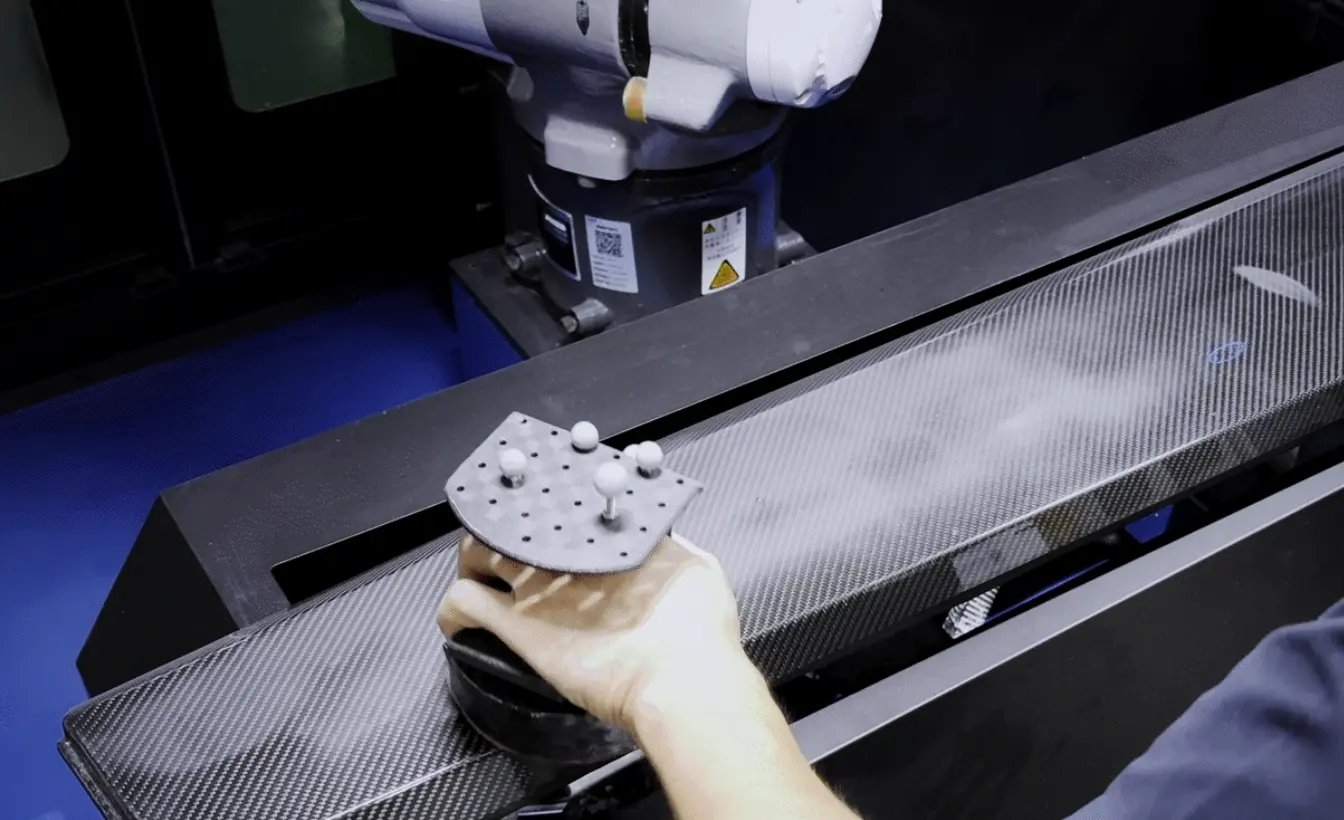

6DoF Joystick

In addition to external tracking, Mimic also supports direct robot guidance. A 6DoF joystick can be mounted on the tool unit, allowing the operator to physically guide the robot in space. This is particularly useful for collaborative robots and for tasks where hands-on fine-tuning is valuable.

Open API for Custom Trackers

Mimic provides an open API for integrating other tracking devices. This ensures that as new tracking technologies emerge, they can be added to Mimic-enabled systems — future-proofing the platform and giving customers flexibility to choose the right technology for their process.

Supported Robots

Mimic works with a wide range of leading robot brands, including:

Powder Coating with Mimic

Powder coating requires precision and repeatability to ensure quality. Using Mimic, operators guide the spray gun once, and the robot can repeat the process flawlessly.

- High-quality, repeatable coating results

- Faster changeovers between product types

- Improved safety by reducing operator exposure

Spray Applications with Mimic

In spray processes, consistency is key. With Mimic, an operator can demonstrate the spray motion once, and the robot will replicate it across all parts with uniform coverage.

- Record and replicate spray paths without coding

- Ensure even material distribution and minimize waste

- Reduce operator exposure to chemicals and overspray

See Customer Cases

Check out what's new in our company !

Ready to Embrace Your Fitness Journey?

Contact us today to embark on your path to a healthier, more vibrant you. Your fitness journey begins here.