Components That Power Our Solutions

At Nordbo Robotics, we design complete robotic systems for surface processing and quality inspection. To make our solutions reliable, flexible, and cost-effective, we’ve also developed a range of components that integrate seamlessly with our software platforms.

Some of our machines use Nordbo-developed components, while others incorporate third-party options from partners like Schunk or ATI. This way, customers always get the right balance between cost, precision, and performance for their application.

Our components include:

Active Compensation Unit (NAC)

Ensures consistent contact force across varying surfaces, improving process reliability without complex robot path adjustments.

Force Torque Sensors

Cost-effective sensors for applications that don’t require ultra-high precision but still benefit from added process feedback.

Flexible Spindle Mounts

Protects tools and spindles from overload and reduces downtime in demanding surface processing tasks.

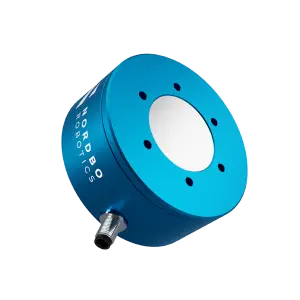

Magnetic Tool Changers (NTC-E10)

Lightweight, pneumatic-free tool changers with optional I/O coupling, designed for quick and simple integration.

Why it matters:

We don’t believe in one-size-fits-all. For high-end, precision-critical applications, we integrate premium third-party components. For cost-sensitive tasks, our own components provide a reliable and practical alternative. In every case, our goal is the same: deliver robust, flexible automation solutions that fit your production needs.

Force Torque Sensors (NRS-6 Series)

Reliable force and torque measurement for surface processes

The Nordbo Robotics NRS-6 series are 6-axis force torque sensors designed for rigid, repeatable, and robust performance. With minimal deformation under load, they provide stable measurements for applications where accurate force control is critical—such as grinding, polishing, buffing, and deburring.

Key Benefits

High precision with minimal deformation

Multiple sizes and payloads to match application needs

IP67 variants for demanding environments

UR+ certified plug & play kit available for Universal Robots

UR+ Kit Includes

NRS-6 Sensor

Mounting flanges

NRC-ETH Ethernet converter

Power & sensor cable

URCap software package

👉 Ideal for: finishing processes, assembly, and other force-sensitive automation tasks.

Nordbo Active Compensation Unit (NAC)

Consistent contact force on complex surfaces

The NAC is a lightweight, easy-to-install unit that ensures constant applied force regardless of surface curvature, tool orientation, or processing speed. By compensating for workpiece or tooling variations, it guarantees accuracy and consistency in surface treatment tasks.

Key Benefits

Accurate, repeatable force control

Lightweight design (only 2.8 kg)

Compact form factor for easy integration

Can be used as both end-of-arm or standalone component

👉 Ideal for: sanding, grinding, polishing, and other surface treatment processes requiring steady force.

Tool Changers (NTC-E10 Series)

Fast, flexible tool changes to maximize robot productivity

The NTC-E10 is a patented magnetic tool changer designed for cobots and light industrial robots. Using electromagnets instead of pneumatics, it eliminates the need for external air supply and simplifies integration.

Key Benefits

Reduce downtime with automatic tool changes

Increase ROI by enabling one robot to handle multiple tasks

Optional I/O coupling module available

Manual and automatic versions to suit different needs

👉 Ideal for: multi-process robotic setups where fast, seamless changeovers are critical.